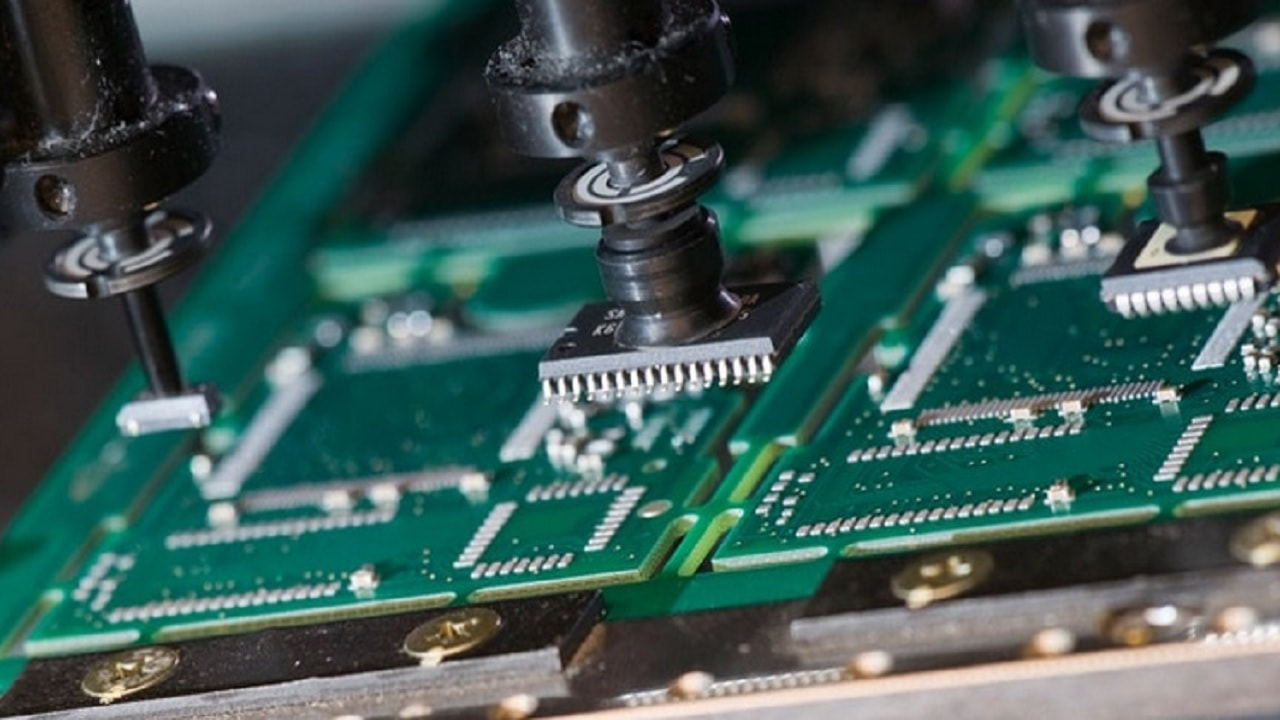

Surface Mount Technology (SMT)

SMT is a modern PCB assembly method where components are placed directly onto the surface of PCBs

using automated machines for high precision and speed.

SMT Capabilities

- Stencil solder paste printing with SPI inspection

- High-speed, high-precision SMT pick-and-place machines supporting fine-pitch components

- Capable of handling 0201, 0402, and micro-BGA/QFN packages

- Reflow ovens with multiple temperature zones ensuring precise thermal profiling

- Automated Optical Inspection (AOI) for quality assurance

- Lead-free (RoHS) and lead-based solder process compatibility

Assembly Process

Solder Paste Printing

Pick and Place

Reflow Soldering

Inspection & Quality Check

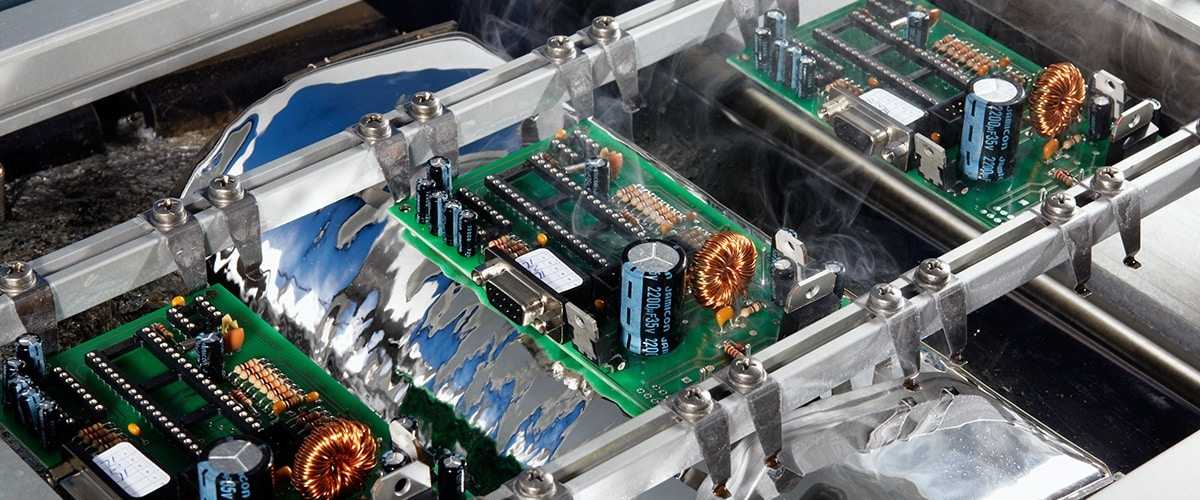

Through-Hole Technology

Traditional PCB assembly technique where component leads are inserted through drilled holes and

soldered solidly to the PCB for mechanical strength.

Through-Hole Capabilities

- Manual and automated component insertion

- Support for a wide range of through-hole components, including:

- i.e., connectors, transformers, relays, capacitors, inductors, and pin headers

- Precise lead forming, trimming, and clinching operations

- Wave and selective soldering processes

- Suitable for components requiring high mechanical stability

- Inspection and functional testing

Assembly Process

Component Insertion

Wave/Selective Soldering

Inspection & Cleaning

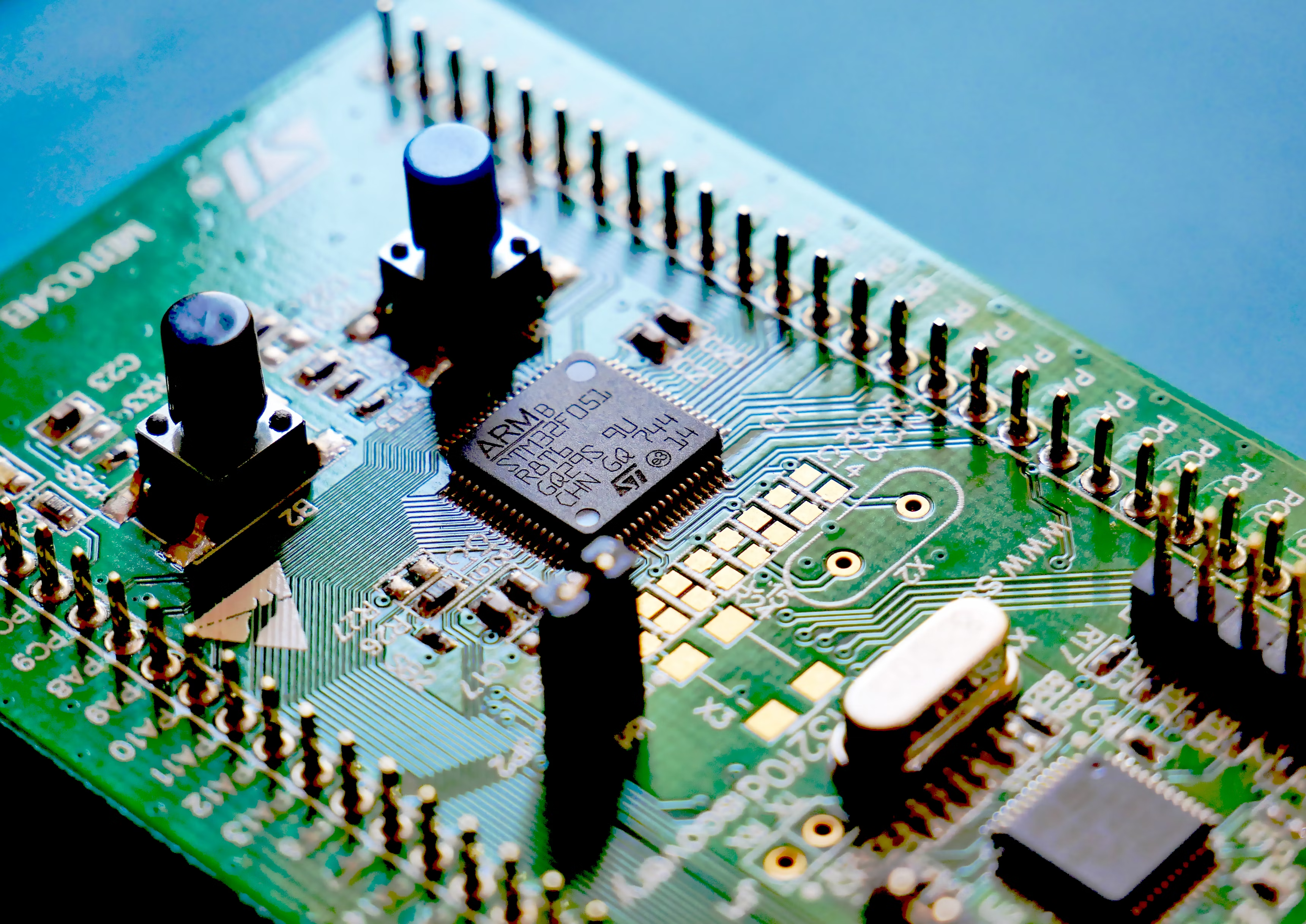

Mixed Technology

Combines SMT and Through-Hole assembly techniques in a single PCB to accommodate diverse components

and complex designs.

Mixed Technology Capabilities

- Fully integrated SMT and Through-Hole (THT) assembly under one roof

- Support for single-sided and double-sided mixed assemblies

- Optimized production flow combining reflow soldering, wave soldering, and selective soldering

- Capability to handle prototype, low-volume, and high-volume production

- Comprehensive Quality Control checks

Assembly Process

Solder Paste Printing (SMT)

Pick and Place & Reflow (SMT)

Through-Hole Component Insertion

Wave Soldering

Inspection & Testing

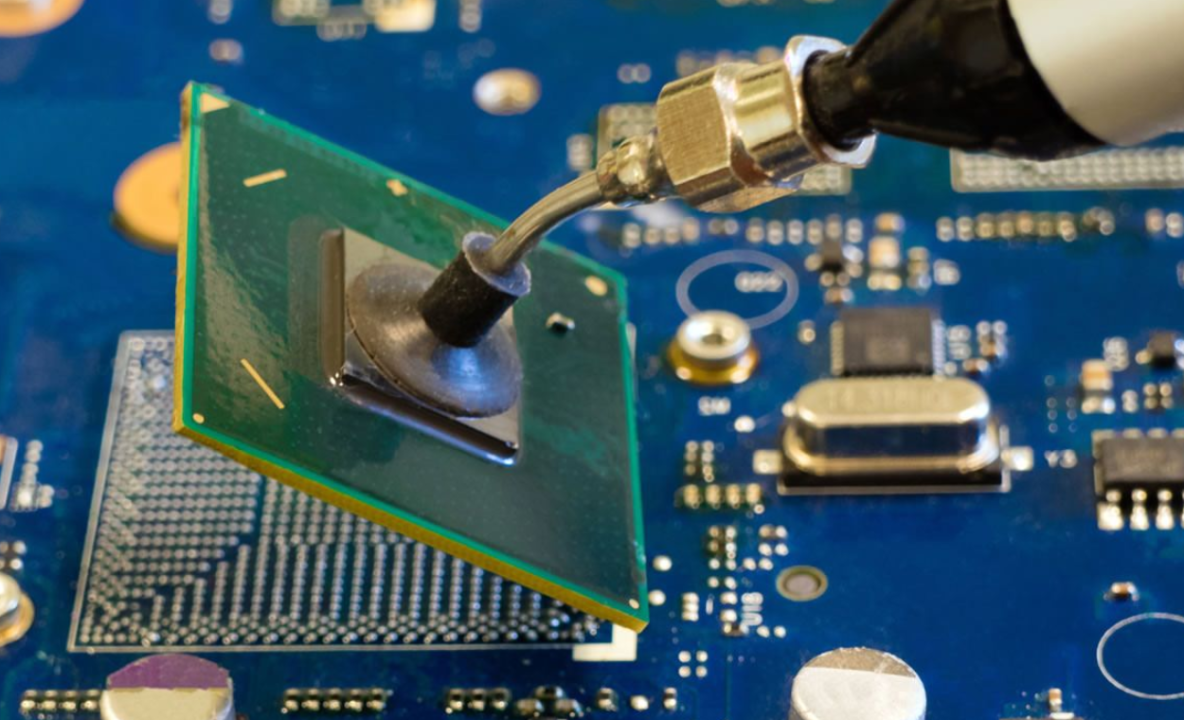

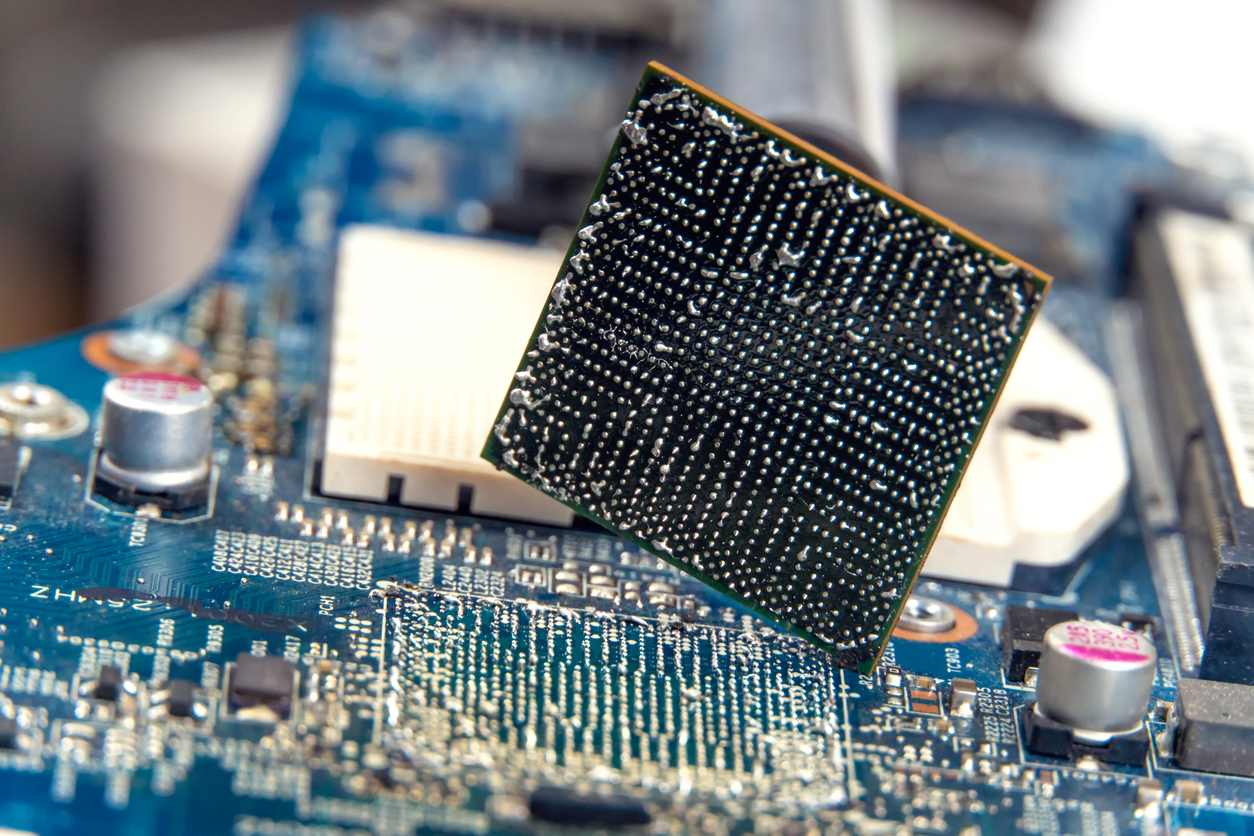

BGA (Ball Grid Array)

Specialized assembly process for densely packed BGAs requiring precise solder ball placement, reflow,

and X-ray inspection.

BGA Assembly Capabilities

- Precise solder ball placement

- Controlled reflow ovens with nitrogen atmosphere

- X-ray inspection for hidden solder joints

- High reliability and low failure rates

Assembly Process

Solder Paste/ Ball Placement

Reflow Soldering

X-Ray Inspection

Functional Testing

User Case

Use Case: Industrial Motor Controller Unit

Industry: Industrial Automation / Motor Control Systems

Objective: Deliver a fully assembled, production-ready motor controller PCB with high thermal reliability and precision soldering.