Single Sided PCB

Cost-effective and reliable single-sided PCBs ideal for simple electronic devices.

Capabilities

- Material: FR4, 370HR, Rogers...etc.

- Board Thickness: 0.8 to 3.2 mm

- Copper Weight: 35 to 105 Micron

- Surface Finish: Roller Tin, HAL, LF-HAL, ENIG, Silver...etc.

- Min Hole Size : 0.3mm*

- Min Annular Ring : 0.1 mm

- Min Track / Space : 0.1 mm

- Solder Mask Colour : Green, Blue, Red, Black, White

- Silk Screen Colour : White, Black

Fabrication Process

Data Preparation & Verification

Imaging & Photoresist Application

Etching

Surface Finish

Inspection & Testing

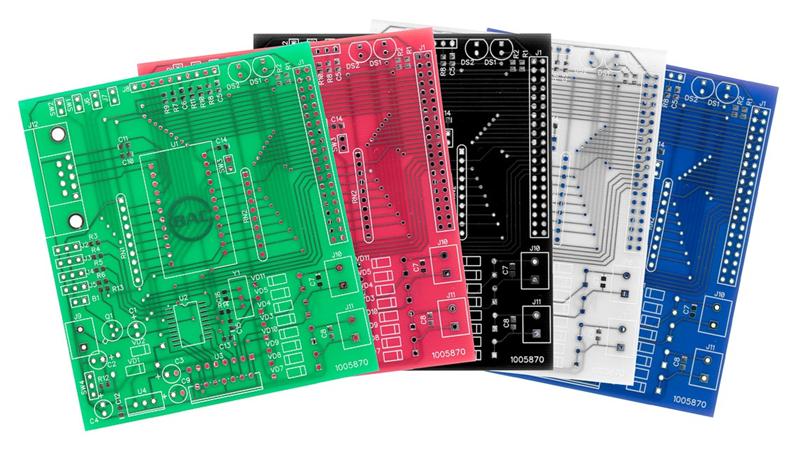

Double Sided PCB (PTH)

High quality double-sided PCBs with plated through holes for complex, dense circuits.

Capabilities

- Material: FR4, 370HR, Rogers...etc.

- Board Thickness: 0.8 to 3.2 mm

- Copper Weight: 35 to 105 Micron

- Surface Finish: HAL, LF-HAL, ENIG, Silver...etc.

- Min Hole Size : 0.2 mm*

- Min Annular Ring: 0.1 mm

- Min Track/Space: 0.1 mm

- Solder Mask Colour : Green, Blue, Red, Black, White

- Silk Screen Colour : White, Black

Fabrication Process

File Verification

Inner Layer Imaging & Etching

Drilling & Plating

Surface Finishing

Quality Inspection

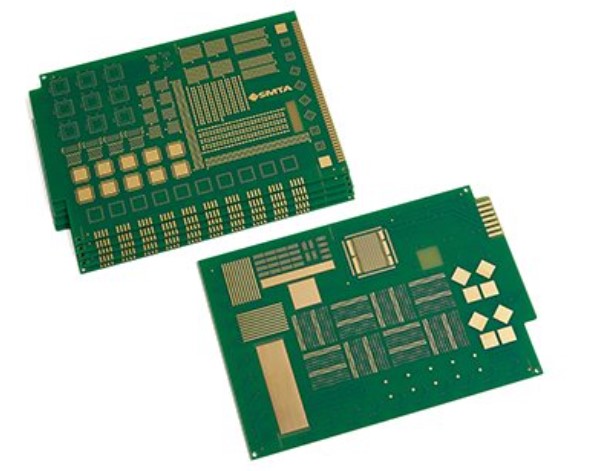

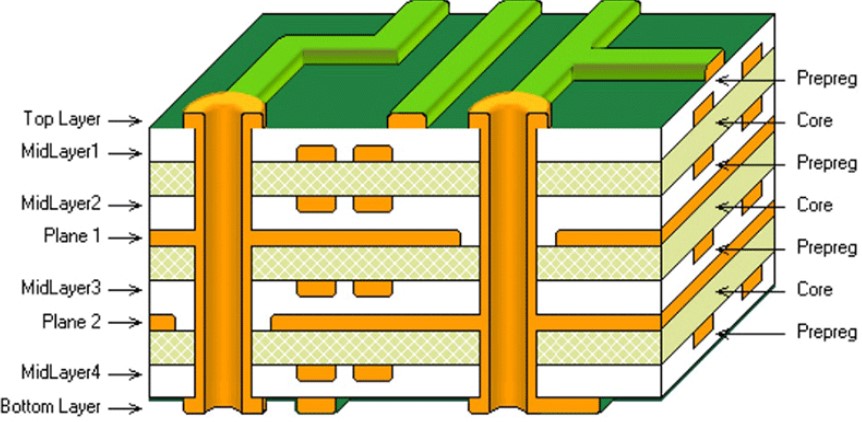

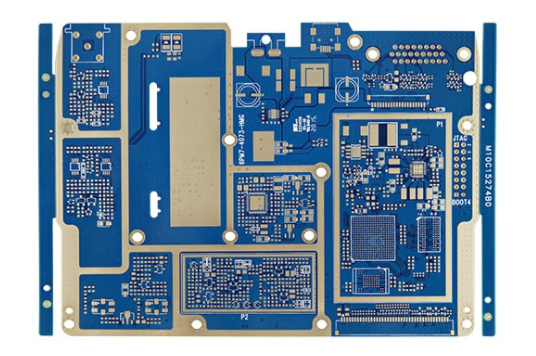

Multi Layer PCB

Multilayer PCBs offering high-density routing, thermal management, and high-speed performance.

Capabilities

- Material: FR4, 370HR, Rogers...etc.

- Board Thickness: 0.6 to 4.5 mm

- Copper Weight: 18 to 105 Micron

- Surface Finish: HAL, LF-HAL, ENIG, Silver...etc.

- Min Hole Size : 0.1 mm*

- Min Annular Ring: 0.1 mm

- Min Track/Space: 0.1 mm

- Solder Mask Colour : Green, Blue, Red, Black, White

- Silk Screen Colour : White, Black

Fabrication Process

Design File Preparation & Data Preparation and Verification

Inner Layer Imaging & Etching

Layer Alignment & Lamination

Drilling & Plating

Finishing & Solder Mask Application

Inspection, Testing & Quality Control

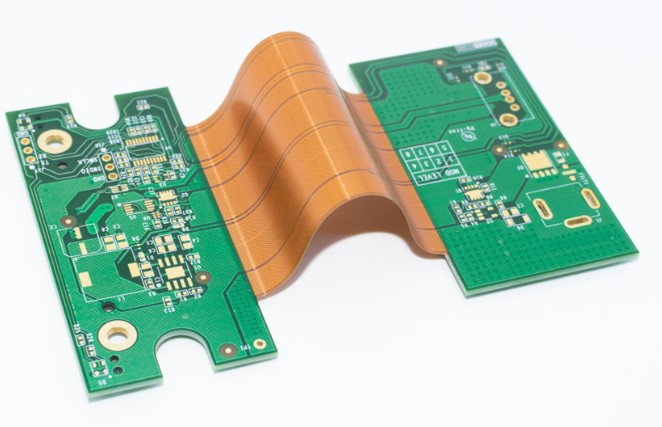

Flexible PCB

Flexible circuits built for dynamic forms and compact designs with excellent durability.

Capabilities

- Optimized bend radius and flex cycles

- Single, double, and multilayer flex options

- Polyimide and polyester substrates

- Adhesive and adhesive-less constructions

Fabrication Steps

File & Material Preparation

Imaging & Etching

Lamination & Curing

Drilling & Plating

Surface Treatment & Solder Mask

Testing & Inspection

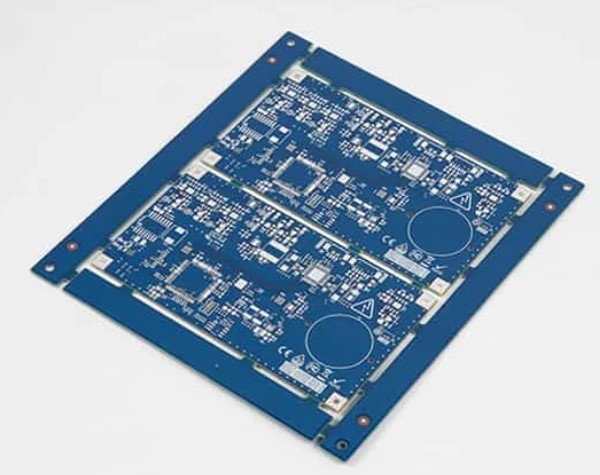

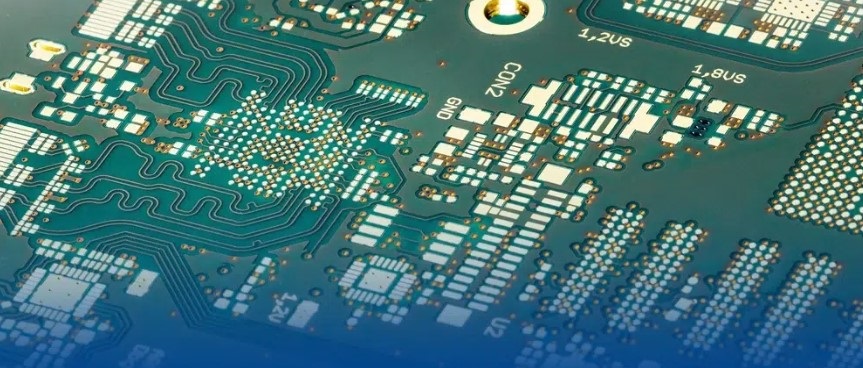

HDI PCB

High-Density Interconnect PCBs with ultra-fine lines and microvias for miniaturization.

Capabilities

- Microvia and blind/buried via technology

- Laser drilling and selective plating

- Fine line and space down to 50 microns

- High reliability and performance

Fabrication Process

Data Validation & CAM Planning

Laser Imaging & Inner Layer Formation

Multi-layer Lamination

Microvia Drilling & Plating

Surface Finish & Final Processing

Final Inspection & Testing

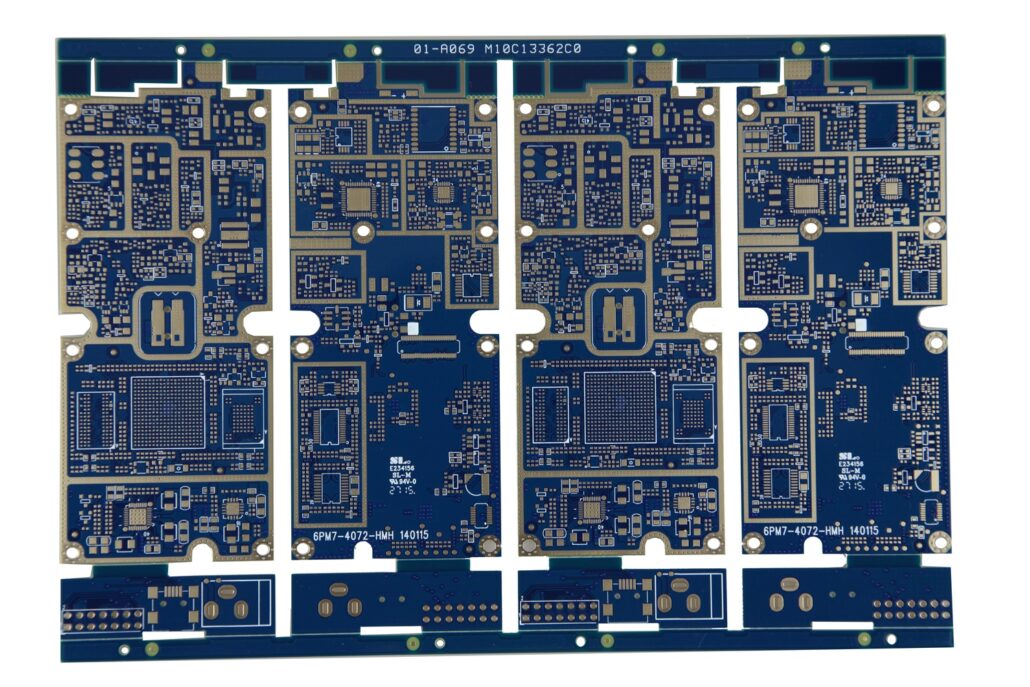

User Case

Use Case: High-Speed Data Acquisition Board

Industry: Test & Measurement / Industrial Electronics

Objective: Fabricate a precision 6-layer PCB for a high-speed data acquisition system with tight impedance control and low signal loss.