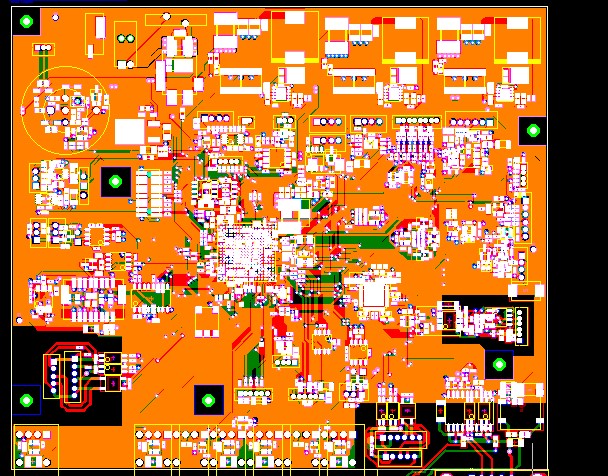

CAM Tooling

Precision CAM tooling ensuring accurate PCB manufacturing and assembly.

RIGID / RIGID-FLEX / FPC

- Input

- Clean Up

- Impedance Verification

- Customer Panel (tab rout / Vscore)

- DFM - Optimization

- Special Process - (HDI, Edge Plating, Edge Castellation, Milling)

- Coupon Creation

- Prod Panel

- Rout, Drill, AOI programming

- ELIC with up to 7 LAM

- Handling up to 60 layers

- Less then 2 / 2 mil (50 my) Technology

- Mix and Match

- Sub Back Drills

- FPC

- output

- Files Review

- Technologically advanced circuit boards

- Fast turn-around service

- Timezone Advantage

- Cost Effective & Efficient

- On-demand capacity

- Building redundancy in critical areas

- Improve automation

Benefits

Quote Data Processing

Preparation of feasiblity report accurate and express mode.

RFQ

- RFQ Data Downloading

- Fab dwg & Specification Verify

- Capture Cost Drivers

- Feasibility Study

- Quotes within hours

CAM Automation

Teqtis automation to improve PCB frontend efficiency and reduce timing.

Scripting

- Programming scripts for leading CAM Tools (Java, csh, Perl, Python ... etc)

- Modifications of existing scripts to extend the capabilities

- Unit / Single Script - workflow customization

- Advanced costing and pricing methodology

- ERP solutions

- Better quality of CAM output and thus reduces shop floor rejects.

- Reducing front-end Engineering cycle time dramatically

- Easy integration with Engineering and shop floor

- Get productive quickly and improve quality

Benefits

User Case

Use Case: Remote Equipment Monitoring

Industry: Industrial Automation / Smart Manufacturing

Objective: Enable real-time visual monitoring of machinery and production lines using embedded camera modules.